The look of plastic labels is impressive and the variety of materials and production types that can be used makes these labels absolute all-rounders.

Plastic labels can be found as key rings, in merchandising, on bags and accessories or as decorative labels on women's, men's or children's clothing. Your design freedom here is almost limitless.

Our team looks forward to finding the best solution for you We look forward to your message!

Plastic labels can be produced from a variety of base materials: Silicone, PVC, PU, TPU, PES, PE, etc.

Depending on the production process, the base materials are used in different forms: liquid, in granular form, as sheets, ...

And are processed differently: Cast, injected, printed, embossed, high frequency welded with other materials, etc.

Request plastic labels

Yes! We offer several sustainable options for plastic labels:

Recycled materials, biological polymers, compostable film, articles made of PLA. All articles can be seen in our sustainability folder begreen (preview). You can request the full sustainability folder here.

Request sustainable plastic labels

Plastic labels are suitable for all areas of product labeling due to their diversity:

Lingerie, sports, casual wear - soft feel and thin material selection make plastic suitable for these areas. Some of the qualities are very flexible and cuddly and ideally suited for use close to the body and skin contact.

Outdoor/ Workwear - Plastic labels can be very durable and weather resistant, making them well suited for outdoor use, whether clothing, furniture, camping, etc. In addition, they are flame retardant, antistatic, or even reflective if required, and have extremely good washing properties, some even resistant to industrial washing.

Menswear/Womenswear - Plastic labels look particularly high-quality and exclusive when combined with materials such as metal or textile.

Other applications for plastic items - key chains, promo items, functional items such as cord stoppers, buckles, adjusters, hangers, etc.

More about labels in our blog

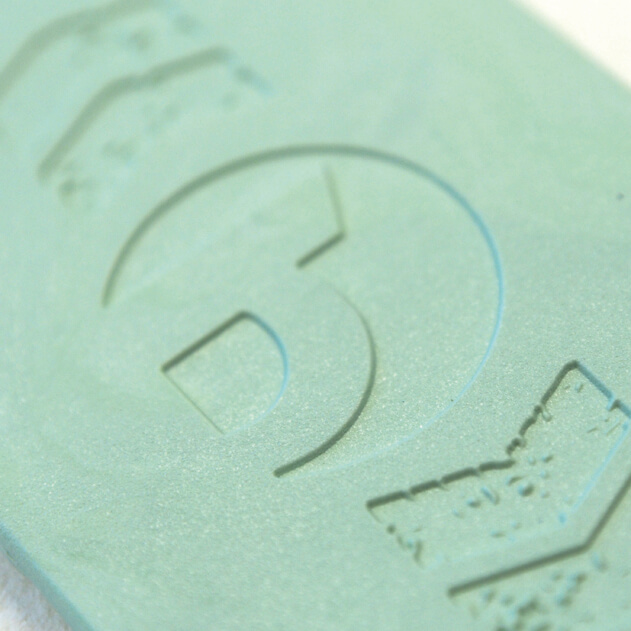

In addition to the properties already mentioned, the classic plastic label is particularly characterized by its 3-dimensionality.

Impressive motifs are created across different levels, either filigree or large, which are not only unusual in terms of area, but also stand out due to their height.

Request advice for plastic label

Crests, badges, key fobs, as a smart label with built-in NFC chip or even as an implementation of a QR code.

The makeup options are variable: individually die-cut as a personalized shape, self-adhesive and iron-on.

Our digital service for product development.

The 3D layouts show the label with relief heights, sewing grooves or frames, material thickness, etc. down to the smallest detail.

Enjoy BRN.CREATE